Food Safety & Quality

Food Safety and Quality is a high priority at Star Snax Foods; therefore, Star Snax Foods guarantees that our customers receive products at a consistently high-quality level.

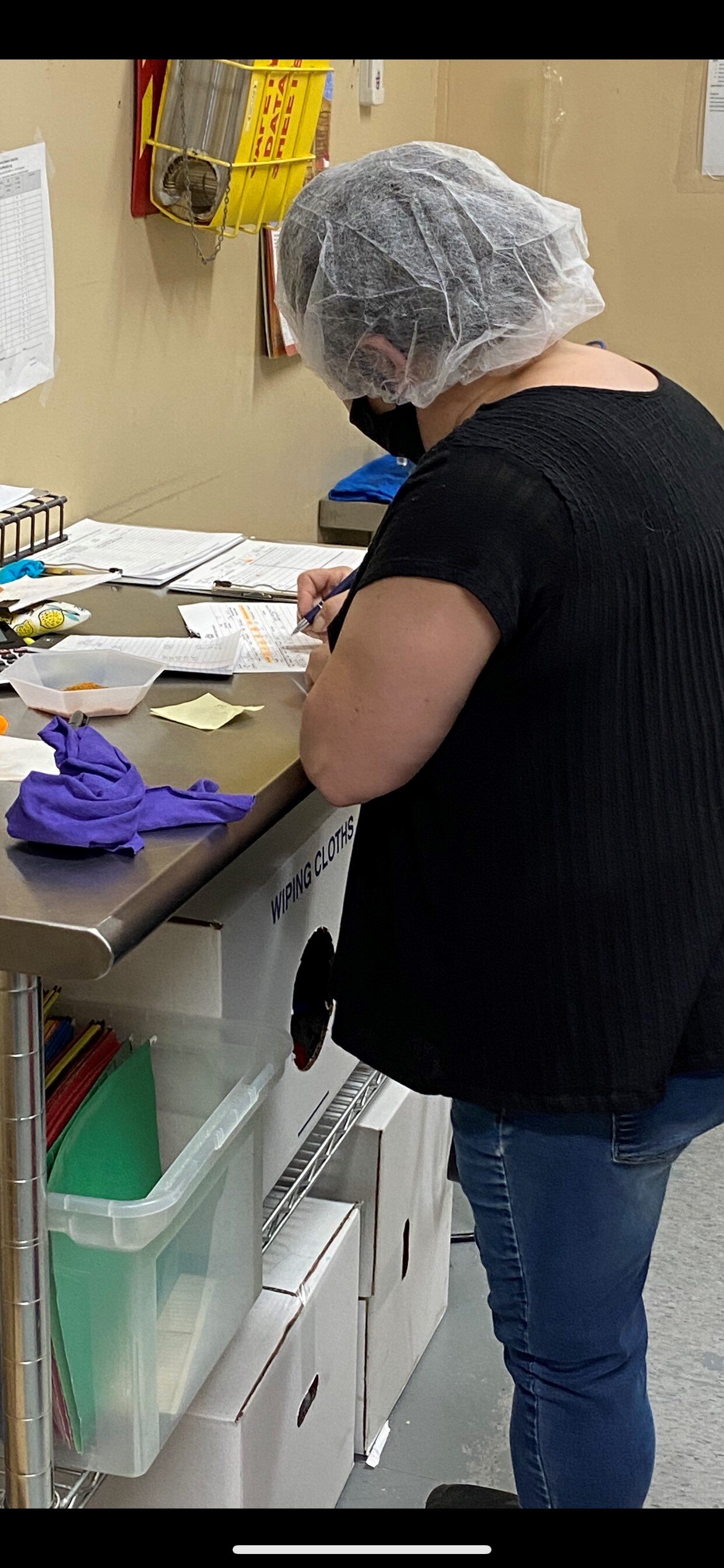

With over 50 years of combined dedicated Quality Assurance (QA) expertise, a QA Technician is available on every shift to provide expert guidance in Food Safety and Food Manufacturing. At Star Snax, we consistently receive high scores on Regulatory and Third-Party Audits.

At Star Snax, we are proud to have the most up-to-date systems in place to protect your product and Brand recognition. Our quality performance, as reviewed by our customers, consistently ranks near the top in all categories.

Certifications

Star Snax ensures quality and safety through numerous third-party quality certifications and regular factory audits. These certifications ensure that Star Snax tracks, documents, and evaluates our work with a professional quality management system. This enables us to continuously develop and improve our performance for you. The certifications we hold are…

Quality Assurance International (QAI) - Organic since 2016

Gluten Intolerance Group – Gluten-Free Certification since 2011

Kosher Certified annually by Chicago Rabbinical Council

Participant in Non-GMO certification of products by Food Chain ID Group

Hogback, white tortilla chips after being cut

Process

Star Snax believes that Food Safety and Quality can be achieved through a simple process. First, Star Snax only sources raw materials from third-party certified suppliers, inspecting them before use. This ensures that we are getting the best possible raw materials. After all, this is where our product starts. During manufacturing and for food safety, the following procedures are implemented…

In-process manufacturing results must conform to established specifications

The final product is reviewed for acceptable results and packaging requirements

All ingredients and finished goods are stored in a secured environment to prevent contamination or adulteration

A high degree of Sanitation employed at all times

Strict adherence to Good Manufacturing Processes (GMP) at all times

Continuous Pest Control Program

Ingredients containing Allergens are stored separately. Equipment is thoroughly cleaned after the manufacturing of a product that contains an Allergen to prevent cross-contamination and is tested for before releasing the line for the next item.

Star Snax educates our employees about all of our products. Star Snax completes the process by assuring that the highest quality product is obtained through frequent testing of the product that is in-process by our qualified Technicians and Managers.

White, hogback tortilla chips entering the fryer

On the Plant Floor..

Star Snax Ovens

Tortilla Chips on Scaling System

QA Tech at Star Snax

Product Packaging

Inline Metal Detection

Incline to the Proofer